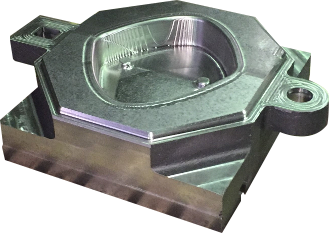

Pressure Die

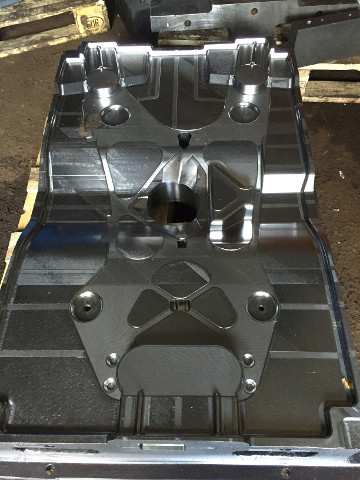

MICRALLOY Tool Steel Pots and Goosenecks for Hot Chamber Die Casting Machines

Micron Alloys have for many years been producing cast components in Tool Steel such as melt pots, crucibles and goosenecks for the pressure die-casting industry.

Tool Steel offers hugely significant benefits over Cast Iron :-

Molten Zinc has an aggressive erosive and corrosive effect on even the tightest grained Cast Iron, these alloys attack the graphite flakes through oxidation opening up the surface allowing further penetration by the molten material. Once this initial penetration has taken place there is a rapid degradation of the Cast Iron resulting in significant and often intolerable ferrite pick-up in the melt bath together with other impurities.

Cast Iron has reasonable thermal conductivity but even thermal fatigue can cause pot failure on high volume zinc machines (relatively low temperature) in as little as 6 months.

MICRALLOY, a Cr Mo V Steel, is a high performance, hot-work tool steel, possessing good strength, impact resistance, hardness and oxidation resistance and excellent elevated temperature properties. This material simply does not suffer erosion from molten Zinc alloys.

Our castings are long-cycle annealed which together with their alloy content promotes a very even grain structure with a matrix of Sorbite or Troostitic Pearlite with a maximum Hardness of 255 BHN. Readily machinable the material is highly resistant to thermal fatigue, the corrosive and any washing and erosive effects of the molten alloy. This structure also results in the molten alloy not being contaminated by Ferrite or Oxide inclusions leading to cleaner melted material, with enhanced mechanical properties.

It is unlikely that MICRALLOY pots will ever require replacing. Currently we have pots in hot chamber Zinc machines which have lasted for 20+ years and are still in service!